CAPABILITIES

At Topeka Foundry & Iron Works we have made a name for ourselves with our fabrication and welding services, both of which form the core of our business. In addition we provide many other services. You can view some of our capabilities and services below.

Okuma 2000 YB 5-Axis

23,000 lbs / 78″

X-Axis: 96″

Y-Axis: 61″

Z-Axis: 53″

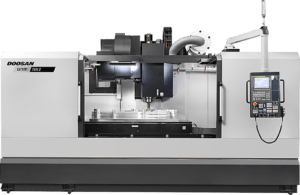

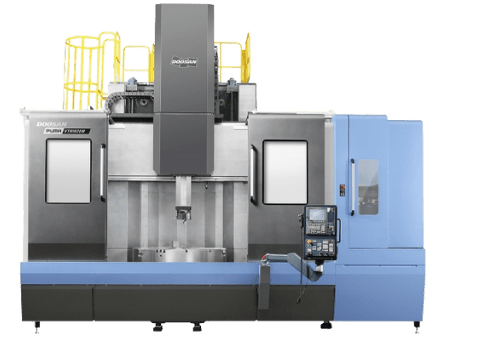

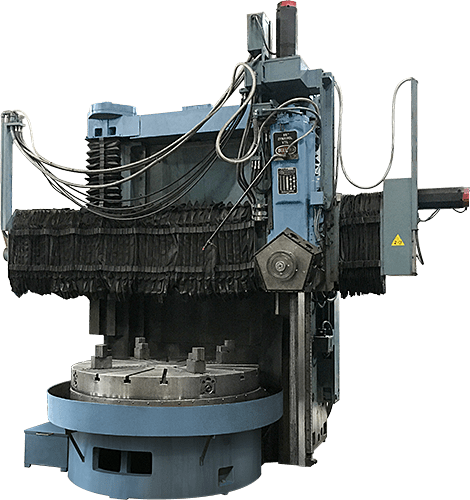

Doosan VTR 1620M

Vertical Turning Center with Live Tooling

X-Axis: 78″

Z-Axis: 70″

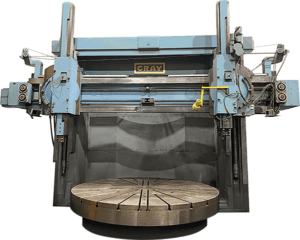

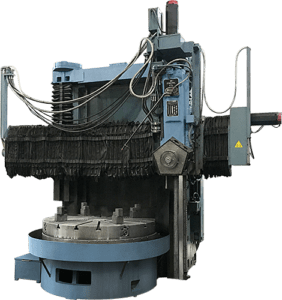

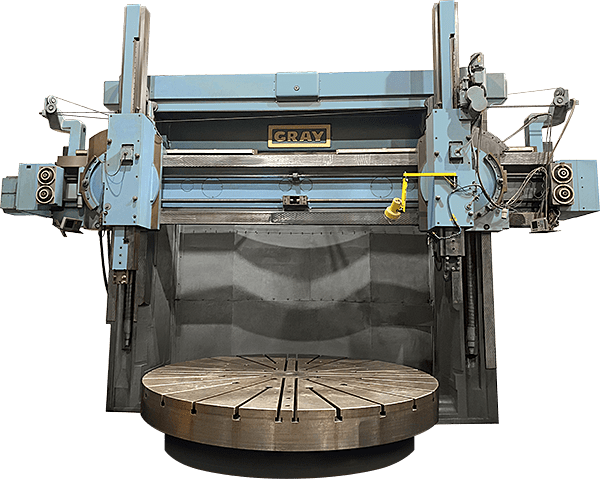

Gray VBM

100 RPM Max; 144″ Table

X-Axis: 168″

Z-Axis: 96″

66″ Bullard VBM

Twin Spindle & Turret, both with C & Radial Axis

X-Axis: 66″

Z-Axis: 64″

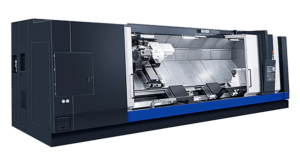

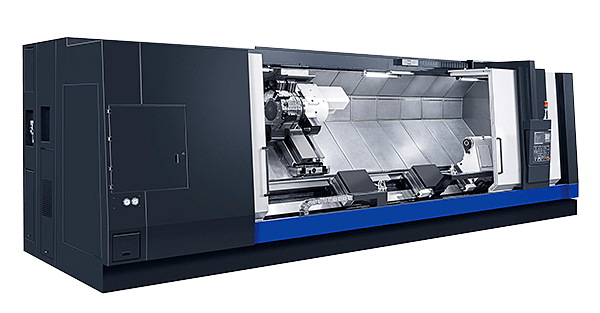

Hwacheon Hi-Tech 850 BB XL

Full C-Axis; Radial & Axial Live Tooling

X-Axis: 36″

Y-Axis: 8.5″

Z-Axis: 196″

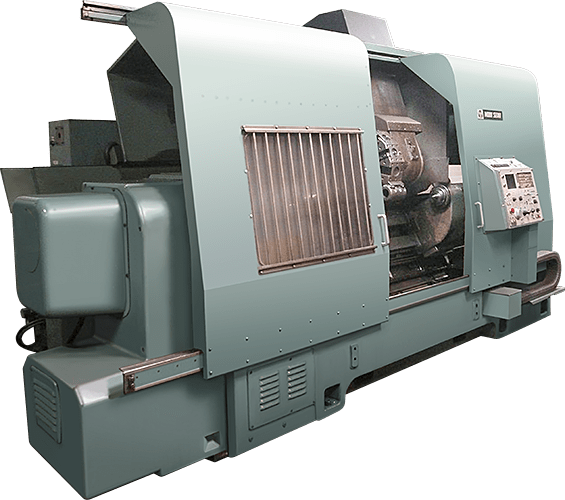

Mori Seiki SL 7

4″ Spindle Bore

X-Axis: 28″

Z-Axis: 61″

Haas SL-30

Full C-Axis; Radial & Axial Live Tooling

X-Axis: 22″

Z-Axis: 34″

Nakamura-Tome WT 150

Twin Spindle & Turret, both with C & Radial Axis

X-Axis: 8″

Z-Axis: 18″

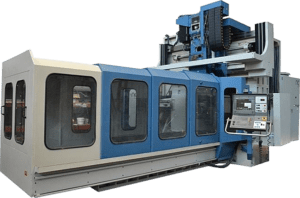

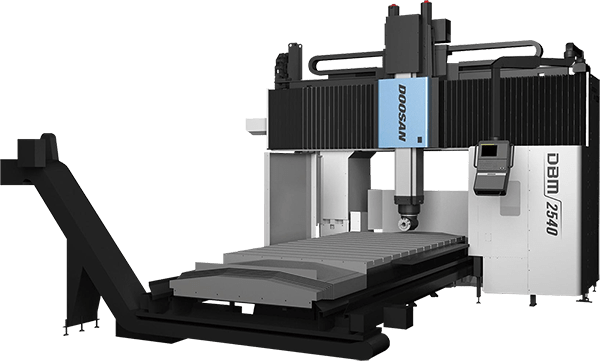

Doosan DBM 2540

Rotary 90 Degree Head for Five Face Machining

X-Axis: 167″

Y-Axis: 118″

Z-Axis: 43″

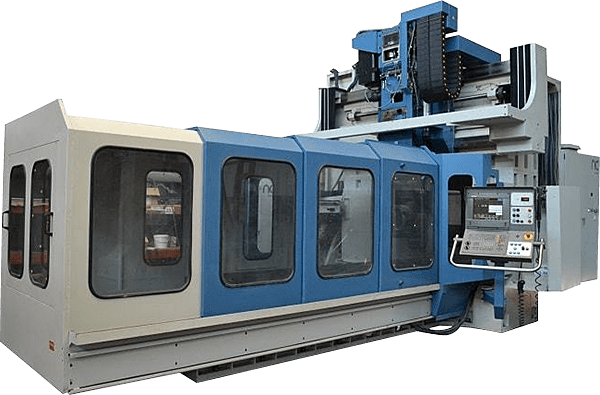

Nicolas Correa 5-Axis FP30/40

Full B & C Axis; Articulating Head

X-Axis: 137″

Y-Axis: 78″

Z-Axis: 39″

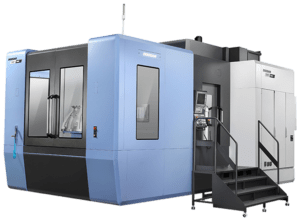

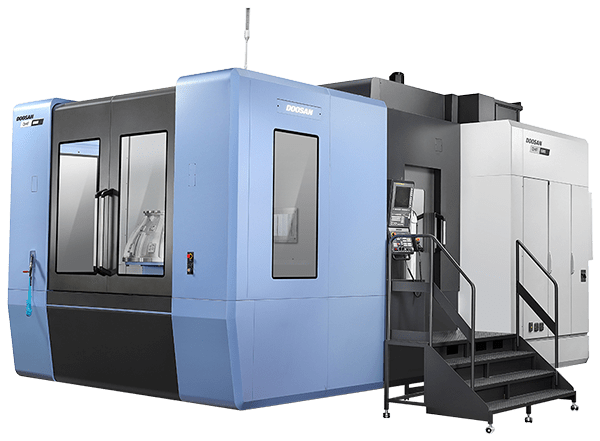

Doosan DHF 8000

Simultaneous 5-Axis; Integrated 24 Station Pallet Pool

X-Axis: 57″

Y-Axis: 47″

Z-Axis: 59″

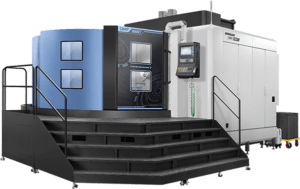

Doosan NHM 4-Axis

Full B-Axis; Integrated 24 Station Pallet Pool

X-Axis: 55″

Y-Axis: 41″

Z-Axis: 47″

Matsuura H Plus-405

Full B-Axis; Twin Pallet Changer

X-Axis: 24″

Y-Axis: 24″

Z-Axis: 24″

Matsuura H Plus-300

Full B-Axis; Twin Pallet Changer

X-Axis: 18″

Y-Axis: 18″

Z-Axis: 18″

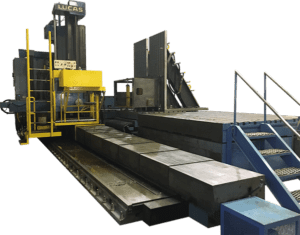

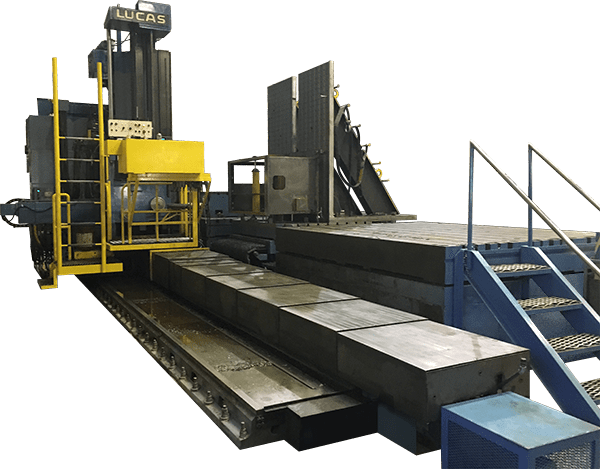

Lucas 642 B288

#6 Bore Mill; 75 Ton Table

X-Axis: 341″

Y-Axis: 96″

Z-Axis: 48″

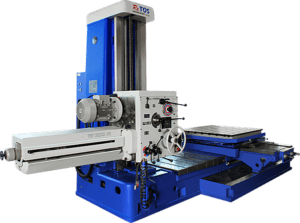

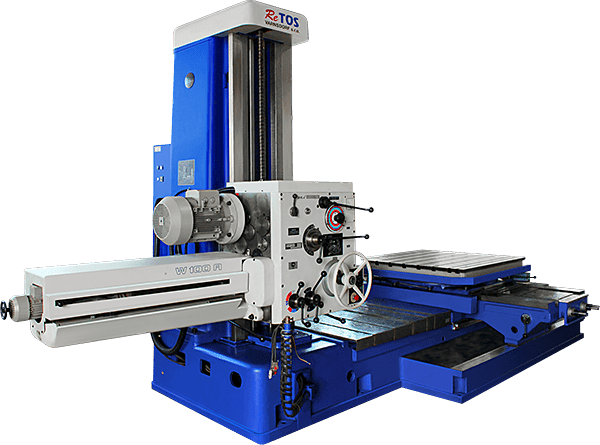

RE-TOS W100A

1120 Max RPM; 13,000 lbs

X-Axis: 63″

Y-Axis: 44″

Z-Axis: 48″

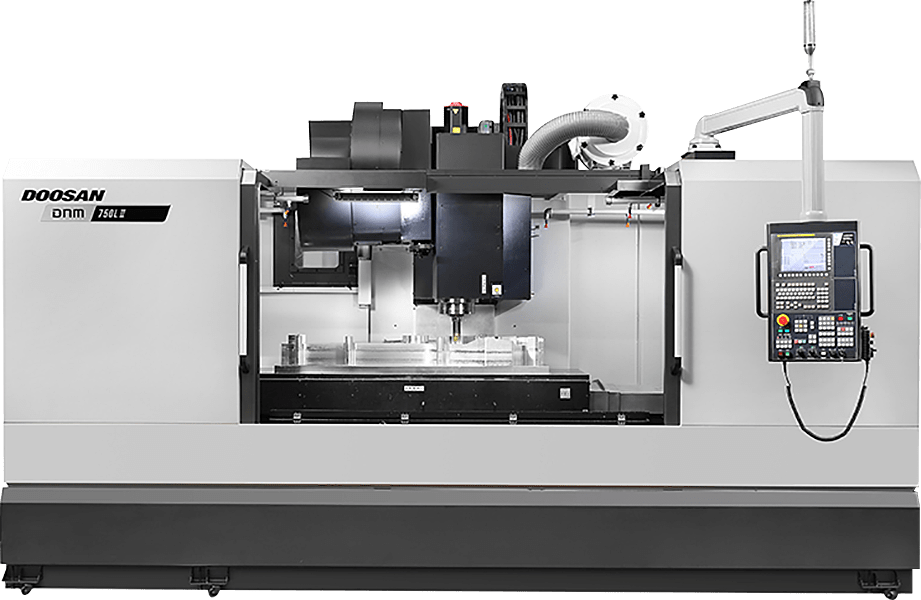

Doosan DNM750L/50 II

X-Axis: 85″

Y-Axis: 30″

Z-Axis: 30″

Kia VX500

X-Axis: 40″

Y-Axis: 20″

Z-Axis: 25″

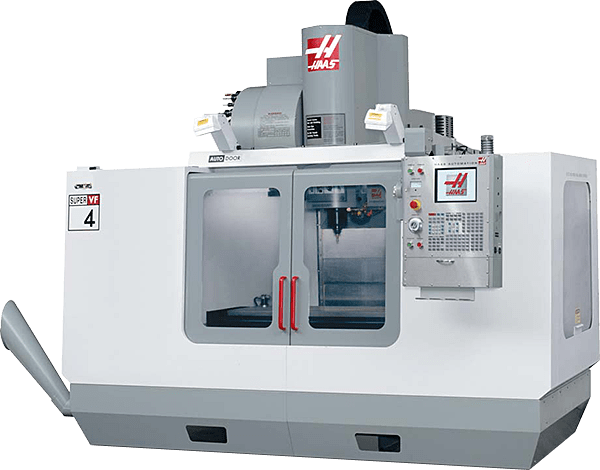

Haas Super VF 4

4th Rotary Axis

X-Axis: 50″

Y-Axis: 20″

Z-Axis: 25″

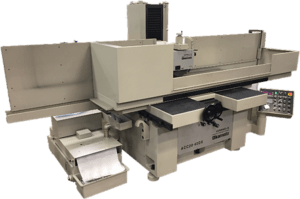

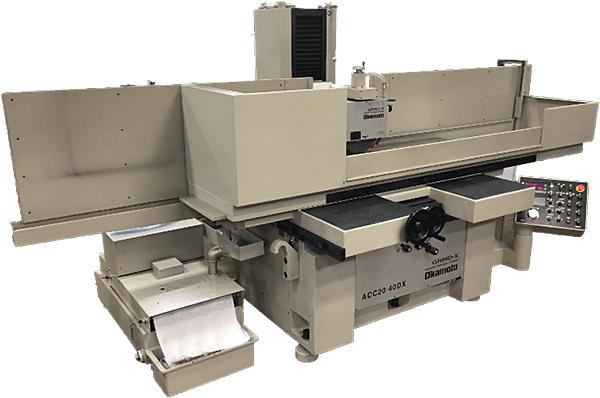

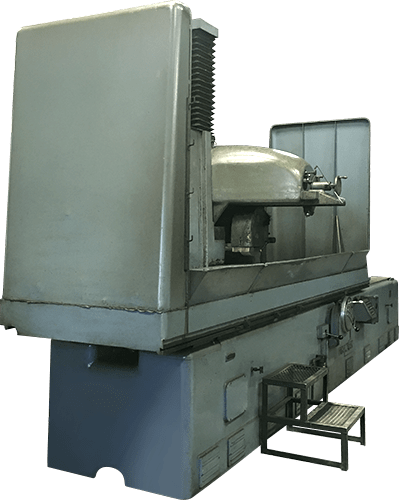

Okamoto Surface

High Volume Grinder

X-Axis: 40″

Y-Axis: 20″

Z-Axis: 18″

Thompson Surface Grinder

X-Axis: 36″

Y-Axis: 96″

Z-Axis: 48″

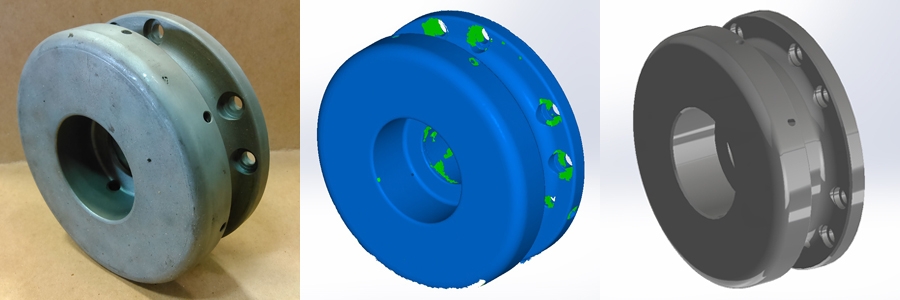

Hexagon Romer Arm

6-Axis; 8″ Measuring Range; .0011″ Volumetric Accuracy; 82″

Sheffield Endeavor CMM

Volumetric Accuracy up to .008mm & .0025mm; Temperature Tolerant; Vibration Resistant

X-Axis: 36″

Y-Axis: 48″

Z-Axis: 40″

Privacy Policy

© 2024 Topeka Foundry & Iron Works