Once the client requests a bid, our Estimators generate price quotes for labor, material and shipping costs for that project, obtains bids from suppliers and subcontractors, and maintains daily communication with project managers. We’re looking for applicants with Construction Science or Engineering degrees and 2 or more years of experience in the construction industry.

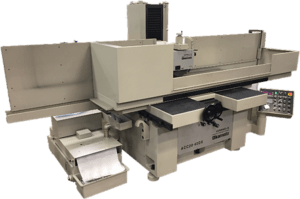

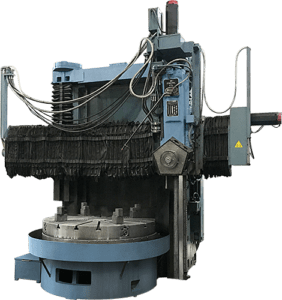

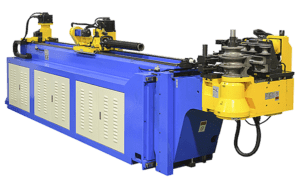

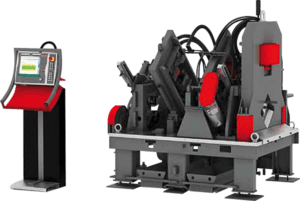

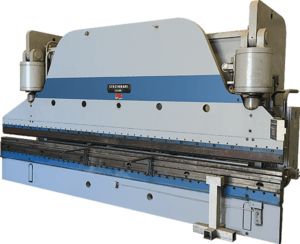

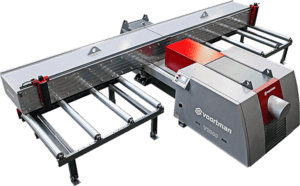

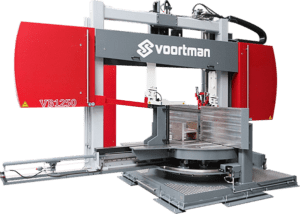

As we continue to expand our array of state-of-the-art precision equipment, the need for quality operators grows as well. We are seeking experienced operators for our band saws, lathes, mills, benders, plasma tables, plate processors, copers, shot blasters and more. Qualified Machine Operators are able to safely utilize material handling equipment, keep all work areas clean and in compliance with safety regulations, and maintain Topeka Foundry’s high Quality Assurance practices.

A Program Manager’s responsibilities include developing long-term relationships with a portfolio of assigned clients while connecting with key business executives and purchasing agents for OEM, fabrication, and machining facilities. Maintenance departments of large industrial and commercial facilities will also be a targeted avenue. As a program manager, you will be required to identify opportunities for account growth while offering customers a full array of value-added services. Program manager will be the liaison between customers and cross-functional internal teams to ensure the timely and successful delivery of our industrial solutions according to the needs of the customer. Great communication skills are a requirement to develop, manage, and maintain favorable relationships with clients

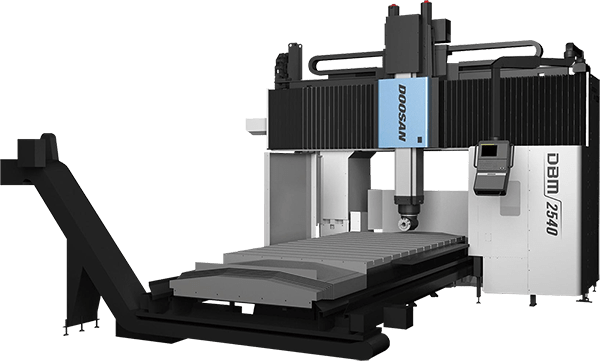

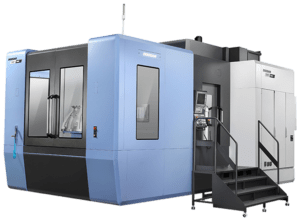

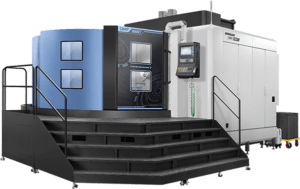

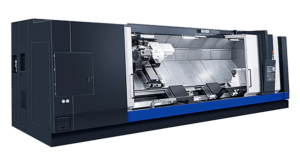

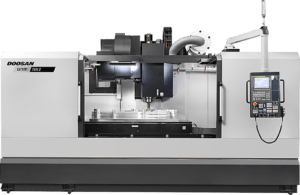

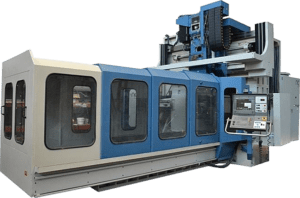

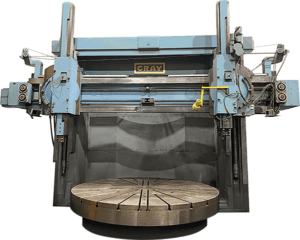

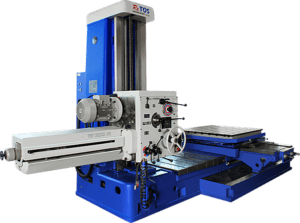

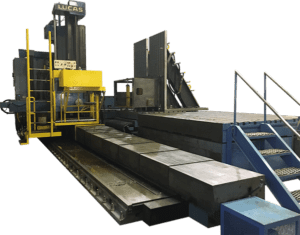

Topeka Foundry and Iron Works is the go-to machine shop for manufacturing companies and defense contractors of all sizes. Not only can TFI create parts and tooling from your design specs, we have the newest precision equipment to mass-produce any part you need. Our production facilities include CNC and manual lathes, mills, and turning equipment capable of light and heavy machining. Our long history of tooling innovation and machine reconditioning has helped our clients overcome productivity bottlenecks and add significant savings to their bottom lines. Our strategic partnerships allow us to buy material at a savings others can’t match.

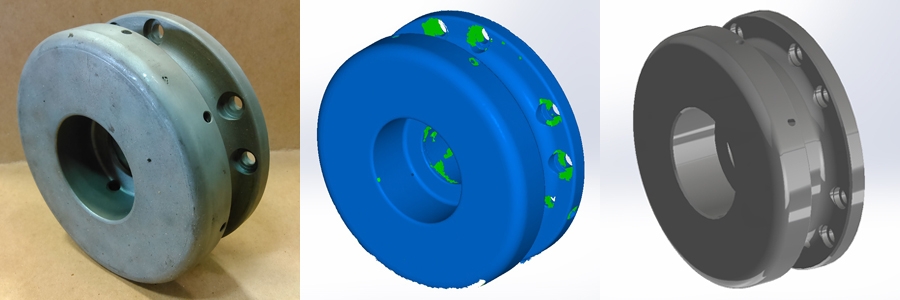

Topeka Foundry & Iron Works has the technology and experience to produce CAD files for each part to the tightest tolerances possible. Our machinists and engineers can also offer advice on improving on your design or manufacturing process. With our expertise on your side, you’ll not only see your dreams proudly come to life, you’ll also see a stronger bottom line.

It doesn’t stop there. Our reverse engineering services can also prevent prolonged stoppages by replacing obsolete parts in your aging machinery. We’ve helped many clients replace broken shafts, gears and other proprietary parts that are no longer available with brand new, and often stronger, components.

We can also help uncover infringement from your competition. If you need documentation to prove your hard work has been benefitting another company, Topeka Foundry & Iron Works can provide the data needed to prove their components or assemblages are suspiciously identical to yours.

Reverse engineering can also keep your company compliant with ever-increasing regulatory requirements. If you have products that you have been manufacturing or selling that have never been accurately detailed, and you now need to provide 2D drawings or 3D models, our team can help you produce them.

Work seamlessly around your schedule while training for your career! Our skilled student program offers on-the-job training on real projects with flexible hours, even weekends.

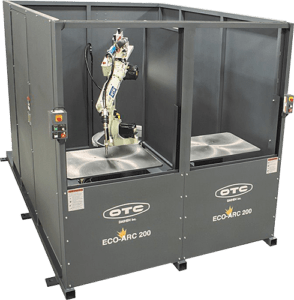

Highly versatile robotic welder produces repeatable, intricate operations. Capabilities Include: High production welding reducing cost and welding times. Improved weld quality through controlled automated process. Capable of welding carbon steel, stainless steel, and aluminum.

[metaslider id=”48″]

[metaslider id=”121″]

In 1982, the first CNC machine was installed. A Mori-Seiki SL7 was purchased new for $100,000 and was paid off in 9 months. Recognizing the need to service Goodyear Tire and Rubber Co., the machine shop greatly expanded its facility, by adding a 16,000 Sq/Ft. addition in 1989. This allowed a Heavy Bay to be built with a 75 ton capacity crane and even larger lathe and milling/turning capabilities.

With the Structural Dept. remaining at 318 Jackson, the Specialty Dept. took over the old machine shop giving them greater efficiency. But by the late 1990s they had outgrown their building. So the old 7Up bottling company building at 129 SE Quincy was purchased to house the Specialty Dept., bringing the sales force and shop employees under one roof. In addition they now offer toilet partitions, toilet accessories, and wood doors. At that point in time they became home to Old Ironsides Lock & Key, with the capability of all locksmith services. The name Old Ironsides Lock & Key, was derived from an old polo club in existence in Topeka, Ks. from the late 1930’s to the late 1950’s.

In 2005 the machine shop again expanded with a 5000 Sq/Ft. addition to house a machine assembly area and have since added 4 large CNC machines in this expansion.

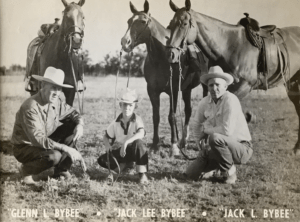

In 1961, 3rd generation Jack L Bybee started working for the company. Today he has 56 years under his belt, of which 36 years are as President. In 1961/1962, a new building was built to house the Machine Shop Dept. and Steel Fabrication Dept. A grand opening was held in 1962 to celebrate the new building. In 1963, a Specialty Dept. was started, offering Republic Steel Doors and Frames, along with finish hardware products. This enabled the company to bid and supply misc. steel fabrication from the Structural Dept. and doors, frames, and hardware from the Specialty Dept. in the Topeka area, and surrounding communities from the Nebraska border to Emporia, and Salina to Kansas City.

By the early 1970s another 4000 sq/ft. machine shop space was added. This allowed for larger lathes and milling machines to be purchased.

In 1979, the company expanded across Jackson St by purchasing the old McPherson/Carlson lumber yard, demolishing and razing it, then building back with a 6500 sq/ft. building equipped with a large shear and saws, a steel yard, and a crane that extended over the street to enable off-loading incoming trucks. Today the company not only stocks Hot/Cold Rolled products, but also special alloys including aluminum and stainless steel products.

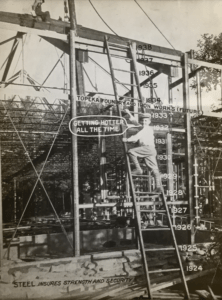

During the depression, the employees were kept busy by building Glenn Bybees’ home. It still stands as the first steel framed home in Topeka. During that time frame, in the best interest of the company, it became incorporated in order to survive the tough times of the depression.

After WWII and a wage dispute, Topeka Foundry & Iron Works Co. closed the foundry and focused on misc. steel fabrication and small machine shop services. At this point the Topeka Foundry & Iron Works Co. 2nd generation, President Jack L Bybee saw an opportunity to develop a machine shop relationship with Goodyear Tire and Rubber which had started a plant in the Topeka area late in WWII. Topeka Foundry & Iron Works Co. saw the opportunity to expand the machine shop which had been used to turn the rough castings provided by the foundry.